Australian standards mandate the installation of safety mesh across roofing planes during construction to protect workers from serious injury and fatalities. Many persons conducting a business or undertaking (PCBUs) mistakenly assume that this mesh represents adequate fall protection for transparent sheet-style skylights to meet compliance standards and protect workers from injury or fatality. In this article, we will shine a light on the dangers and potential false sense of security that roof safety mesh can give workers and PCBUs and what genuine height safety compliance requires.

The Problem with Skylight Safety Mesh

Roof safety mesh is considered a passive fall arrest system as it does not prevent a fall from occurring but seeks to minimise harm to the individual who has fallen. Under the Hierarchy of Control Measures, these types of systems are considered among the least effective, second only to active fall arrest. Preventative systems like skylight covers, guardrails and walkways or work positioning systems that physically prevent a worker from accessing a skylight void should always be implemented wherever practicable to do so.

There are three core reasons why we at Anchor Safe believe roof safety mesh is not only often non-compliant with Australian height safety standards but also puts the lives of workers in serious jeopardy.

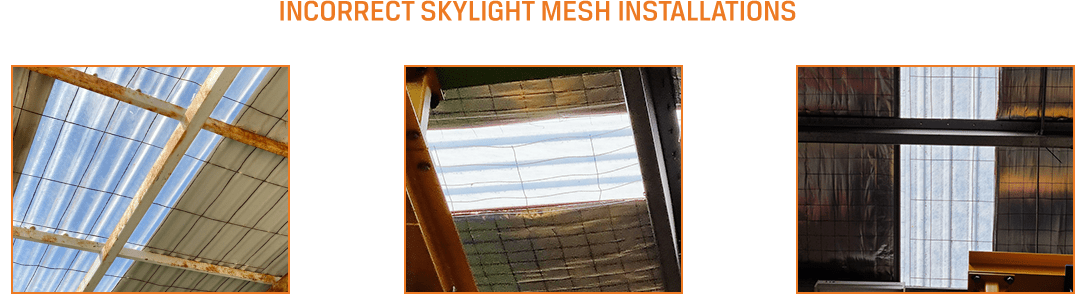

1. Improper installation:

We’ve conducted thousands of height safety audits throughout Australia and it is not uncommon to find roof safety mesh improperly installed and secured. Where mesh is not installed in strict accordance with manufacturer installation guidelines it must be considered non-compliant and can not be relied upon to save a life in the event of a fall.

Many construction companies cut costs by using substandard materials or, in extreme cases, chicken wire instead of certified safety mesh. For true compliance and effective fall protection, only mesh that meets rigorous design and testing standards can be used.

2. Difficult to inspect & maintain:

There are no ongoing maintenance or inspection requirements that are specific to roof safety mesh. However, if mesh is to be relied on as a primary fall protection system, it must be routinely inspected and deemed fit for the task of fall arrest which can exert sudden and significant force on the mesh and its fixings.

Inspecting roof safety mesh can be particularly difficult, time-consuming and expensive to achieve. If the mesh is found to be defective there is little option for repair, the mesh must be replaced. Again, doing so comes at great difficulty and significantly increased costs.

Keep in mind that finding a defective mesh system is a best-case scenario. Far too often mesh systems are out of sight and out of mind and a PCBU will only realise they are defective when they fail to properly prevent a serious injury or death.

3. Life span:

Roof safety mesh has a finite lifespan. Mesh degradation from corrosion, poor installation, or aging can drastically reduce its effectiveness in arresting falls. Using lower-quality mesh to reduce costs can further shorten its useful lifespan. PCBUs can often be caught unaware, incorrectly believing their mesh is relatively new only to find it is already severely corroded when we inspect it.

Our height safety audits have uncovered some seriously degraded mesh systems that workers have been relying on for their wellbeing and safety when working on rooftops. Once the mesh has begun to degrade like this, the system is non-compliant and no longer fit for the task of fall arrest and must either be replaced or better preventative systems installed.

The PCBUs Responsibility for Skylight Safety Mesh

The responsibility for maintaining a safe work environment rests squarely on the shoulders of the Persons Conducting a Business or Undertaking (PCBUs). Australian workplace safety laws, including the Work Health and Safety Act, impose stringent obligations on PCBUs to manage and mitigate the hazards associated with skylights.

- PCBUs are required to actively identify potential fall hazards like skylights and take all reasonably practicable steps to reduce these risks in accordance with the Hierarchy of Control Measures. This includes ensuring that any skylight and associated safety measures are not only present but are also adequate and compliant with Australian safety standards.

- PCBUs are required to ensure that the installation of roof safety mesh aligns with manufacturer guidelines and adheres to Australian standards such as AS/NZS 4389. This includes verifying that the mesh is of suitable manufacture, is correctly anchored and that installation has not altered its efficacy as a safety barrier.

- PCBUs are required to undertake regular inspections and maintenance of roof safety mesh. They must routinely check the mesh for any signs of wear, corrosion, or other damage that could undermine its structural integrity and efficacy as a fall prevention measure. If any part of the mesh is found to be deteriorating or otherwise unsuitable, it is the PCBU’s duty to replace or repair it promptly.

A Better Alternative; Preventative Height Safety Measures for Skylights

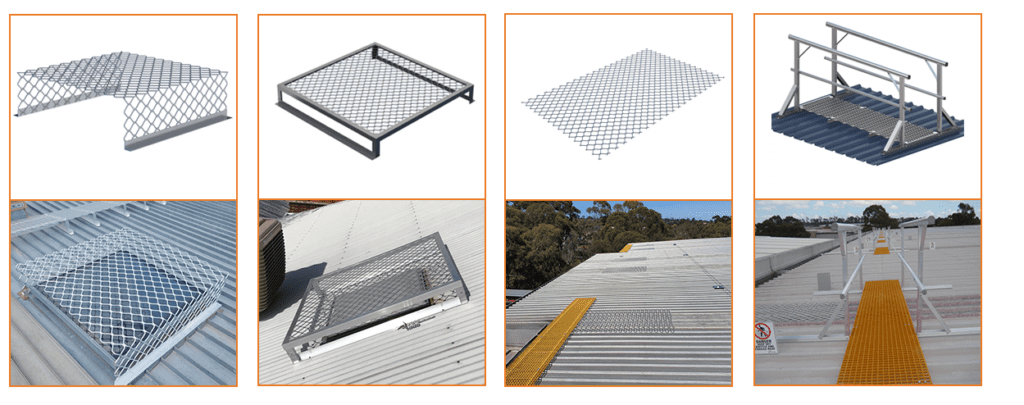

The best way to stop a worker from falling through a skylight is to prevent their ability to step or fall on them. Preventative measures like skylight protection covers, roof walkways with dedicated skylight crossovers and guardrails are highly effective passive systems. These systems not only enhance safety and compliance but also align with the hierarchy of control measures, prioritising fall prevention over less desirable fall arrest methods.

These systems are simple to install and easy to inspect and certify for height safety compliance, greatly reducing the PCBU’s risk exposure and long-term costs. Their passive nature ensures they are simple and intuitive to use meaning no specialised training is required.

Where installation of passive systems like these is not practicable, A PCBU may consider a work positioning or fall restraint system. This will typically include an anchor point or static line to which a worker can attach a lanyard that can physically restrain them from accessing a skylight void.

These systems are considered ‘active’ as they rely heavily on PPE and correct use by the worker. Therefore, work positioning/fall restraint systems are considered less desirable compared to the passive systems above in accordance with the Hierarchy of Control Measures. These systems will require specific training and site induction before use. Seek advice from a reliable height safety advisor like Anchor Safe before relying on these systems to protect your workers.

Get an Expert Opinion on Your Skylight Safety Mesh

If you’re unsure if your skylight safety mesh is compliant and ready to save a life, it is crucial you engage a reputable height safety expert to assess your roof. Anchor Safe can provide a comprehensive audit of your roof safety compliance and provide expert guidance on what steps you need to take to minimise your risk.

Our experienced height safety technicians can design, supply and install passive or active skylight protection on your rooftop. Every Anchor Safe skylight protection system is designed to suit the specific needs of your site by our experienced and highly trained height safety specialists. We’re confident in the quality of our work, so all our height safety systems come backed by our 10-year product & installation warranty

For more information on skylight protection or to organise a free quote, contact our friendly team